The History of the Iron Bridge

The world's first iron bridge was built over the River Severn at Coalbrookdale, England in 1779.

This now world-famous industrial monument gave its name to the town that grew around it and to the spectacular wooded gorge that surrounds it.

This gorge is now a UNESCO World Heritage Site and highly regarded as the birthplace of the Industrial Revolution.

Why the Ironbridge Gorge?

The Ironbridge Gorge is an area rich in minerals, coal, iron ore, limestone, sand, and useful clays.

In the second half of the 1500s, local landowners began to exploit coal on a large scale and make use of the River Severn as a form of transport. Tradesmen were attracted to the Gorge for work. By 1700 there were several furnaces and forges in the area, all using water power to work their bellows and charcoal as their fuel.

THE DARBY FAMILY AND IRON

In 1708 the blast furnace in Coalbrookdale (now the Old Furnace) was leased by Abraham Darby, a Quaker, and a pot founder. A year later he began to use coke as the fuel to smelt iron (instead of charcoal). This momentous development made possible a vast increase in iron production in Britain, part of the series of dramatic changes known as the Industrial Revolution.

After this, generations of the Darby family and other ironmasters fostered a remarkable series of innovations in the use of iron.

Picture shows engraving The Upper Works at Coalbrookdale, produced by François Vivares after Thomas Smith and George Perry, and published in 1758.

The problem of crossing the river

There was an increase in traffic on the River Severn and only ferries and one bridge to cross it.

In 1773 Thomas Farnolls Pritchard, a Shrewsbury joiner turned architect, wrote to the local ironmaster and entrepreneur John Wilkinson, suggesting an iron bridge across the river. His 1775 design proposed a single arch, thus causing no obstacle to boats.

A group of local businessmen commissioned ironmaster Abraham Darby III to build the bridge. For Darby this would advertise the versatility of cast iron and the Coalbrookdale Company's skills.

Building the bridge

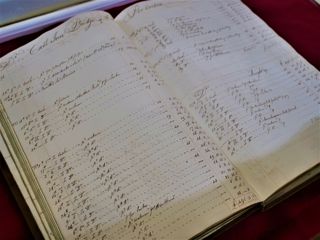

Work began in November 1777. Abraham Darby III estimated the bridge's cost at £3,200. 384 tonnes of iron would have been needed to build the bridge (it would have required three months of continuous production in one of Darby’s furnaces to make this amount).

At which local furnace the iron members for the bridge were cast is not known for certain. It must have been a tremendous feat to cast, transport and raise these enormous structures.

A pioneering monument

The final cost of building the Bridge was £6,000 (if Abraham Darby had wanted to build such a bridge today, he would have to raise in the region of £1.5 million).

Darby’s bridge was the first in the world to use cast iron structurally, and artists, writers, spies and engineers came from all over the world to marvel at ‘that most incomparable piece of architecture’. Today, visitors continue to travel from around the world to see it.

Image shows The Cast Iron Bridge Near Coalbrookdale by William Williams, painted c.1780.

-

![]()

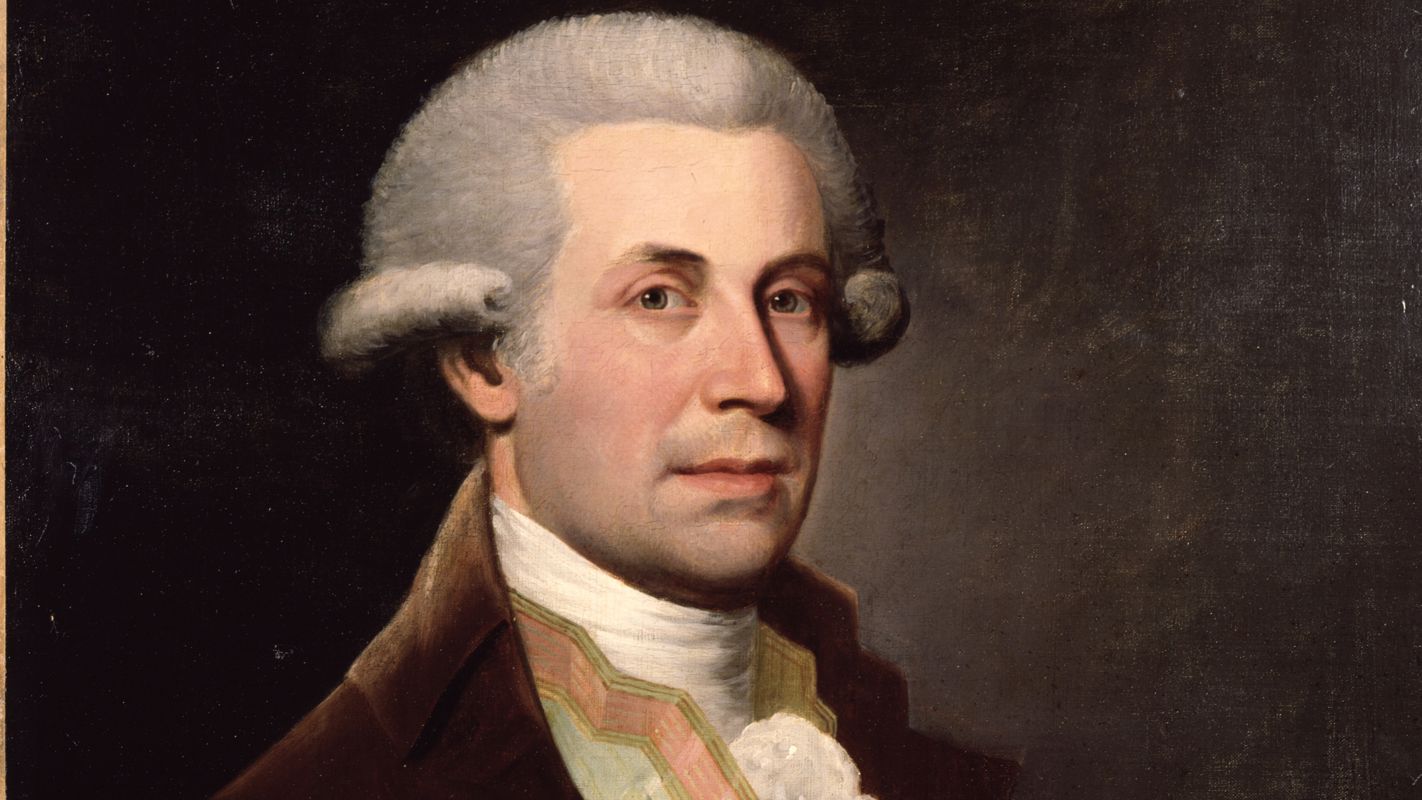

Who's who

Find out more about some of the people involved in the development of the Ironbridge Gorge and the building of the Iron Bridge.

Today you can walk across the bridge it and admire spectacular views of the Gorge. Take a free visit to the Iron Bridge Tollhouse to learn more about this magnificent monument’s history.